Overview

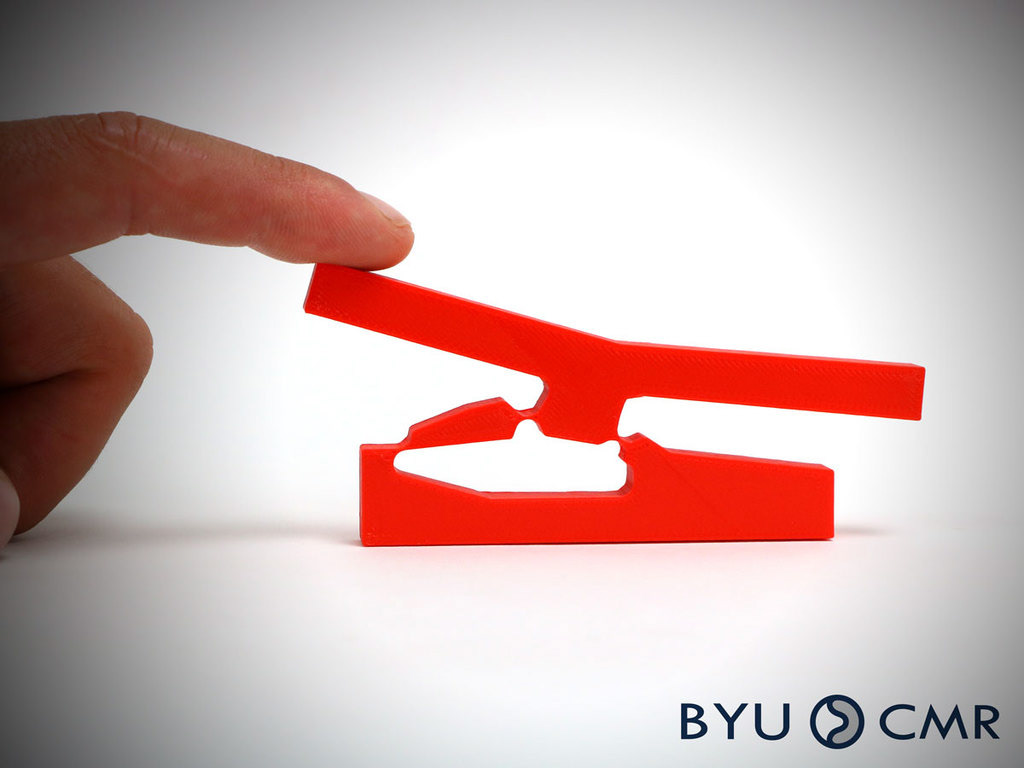

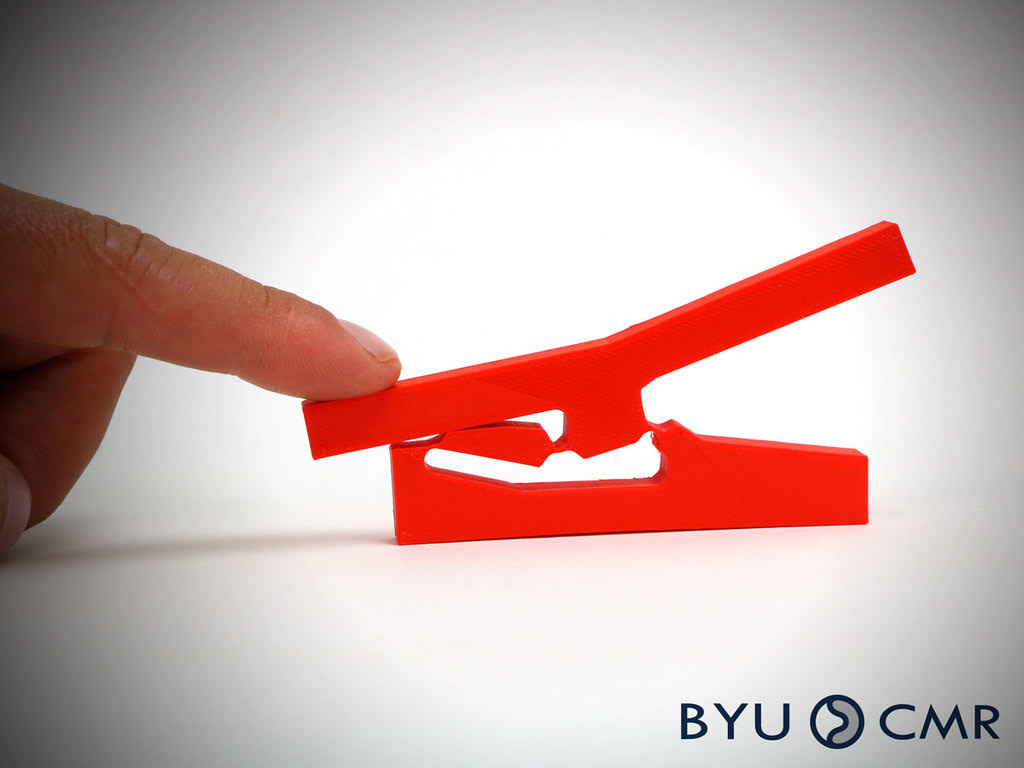

I wanted to explore the potential of compliant mechanisms with bending joints instead of hinges. My final design was a single 3D print flexing shape.

Although my most successful version used TPU (flexible filament), by tweaking the hinges normal PLA filament should provide enough flexibility as well.

Demo

After testing over 300 cycles on its bending ability, it still shows no sign of the TPU filament breaking.

Using TPU made the support material harder to remove, but as mentioned above later iterations could hopefully use any kind of filament.

Inspiration

After watching a video about compliant mechanisms I was hooked. The potential applications of microscopic mechanical devices, advanced 3D printing, and surgical tools were fantastic, but above all else, I liked the idea of advanced bendy machines.

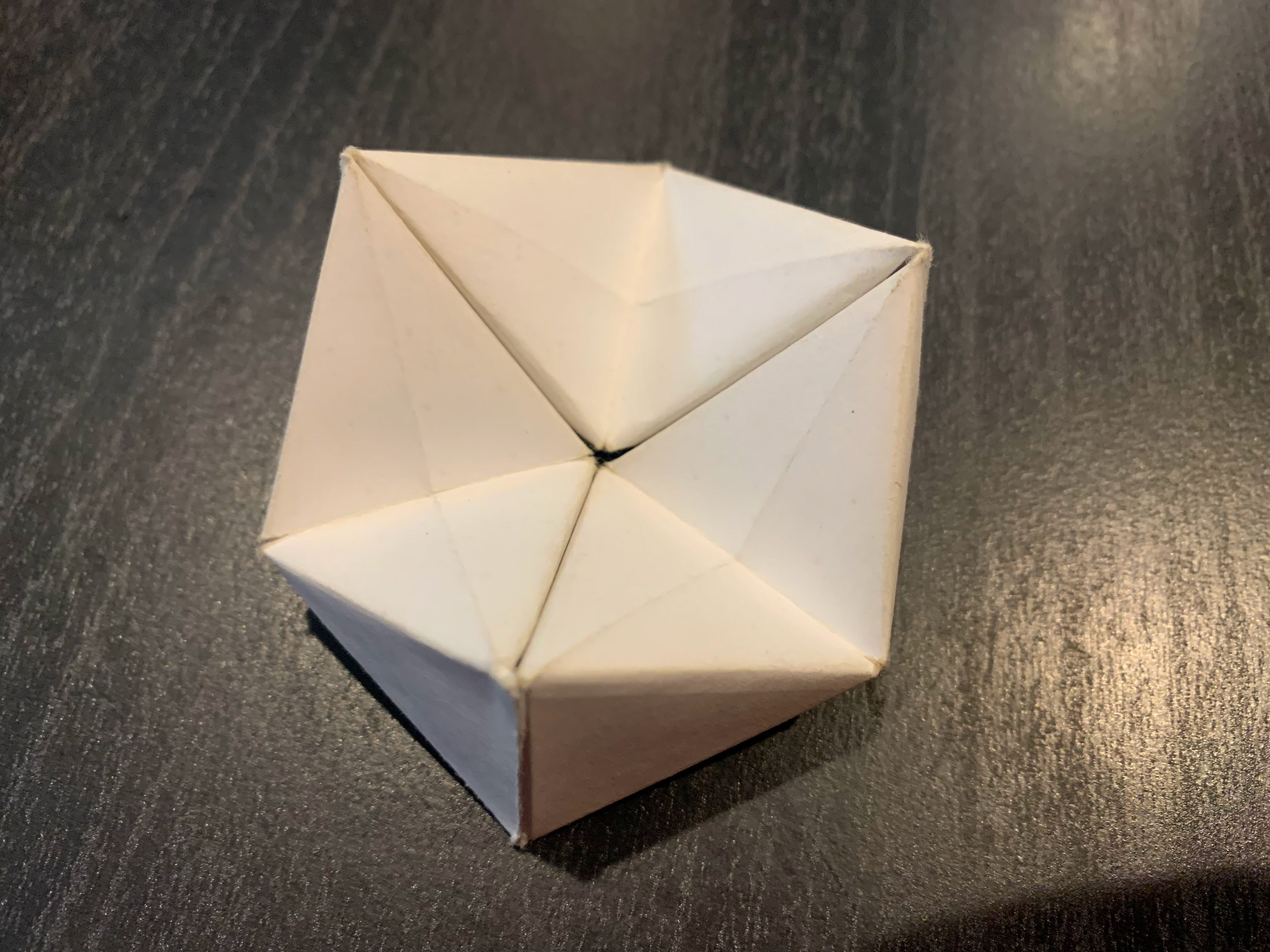

Meanwhile, I had recently followed an interesting origami fold tutorial. The result was the "flexagon" shape that led to my final design. I realized if the flexagon could be folded from a single piece of paper, it could be 3D printed in a single part.

Design Iterations

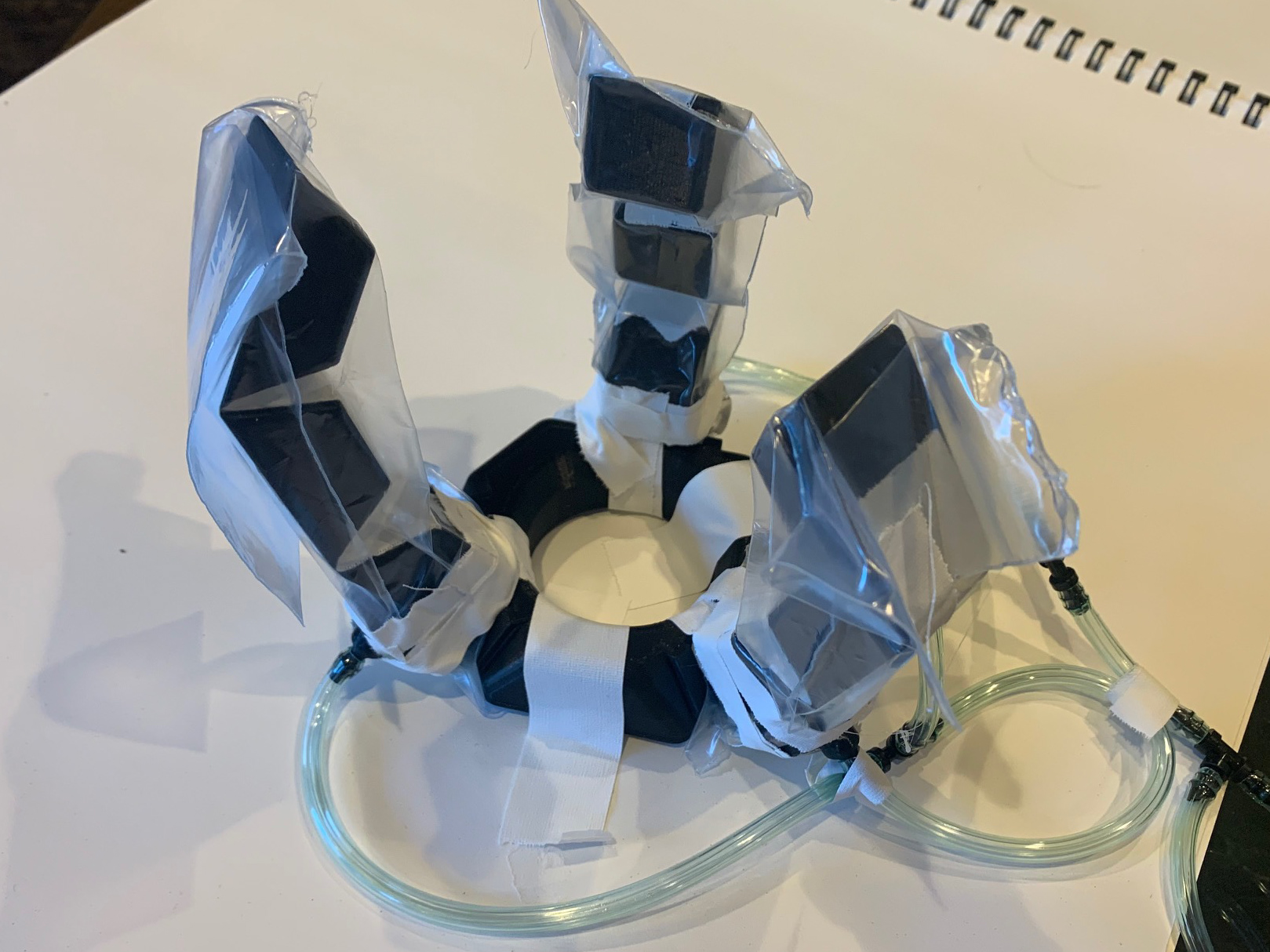

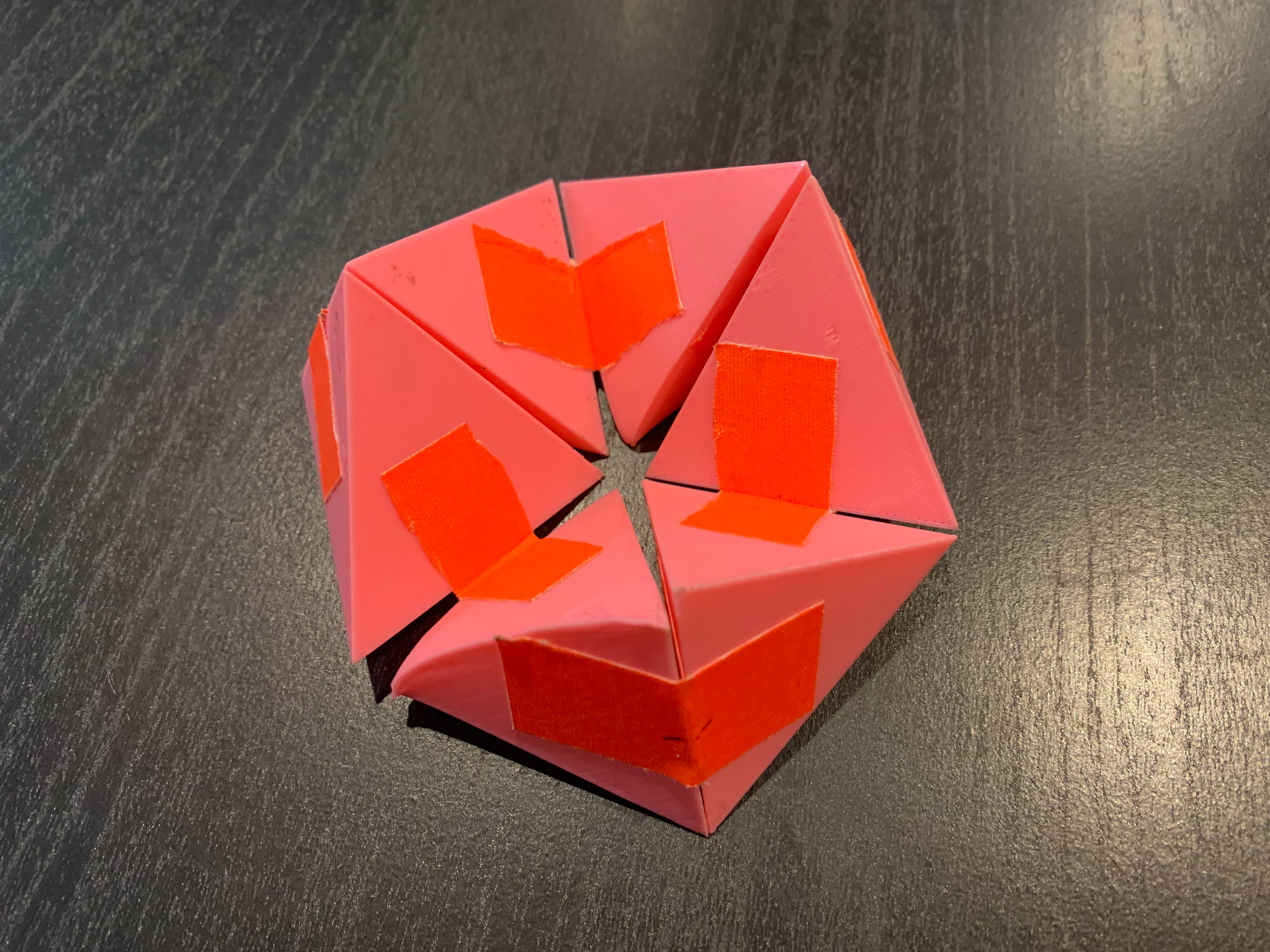

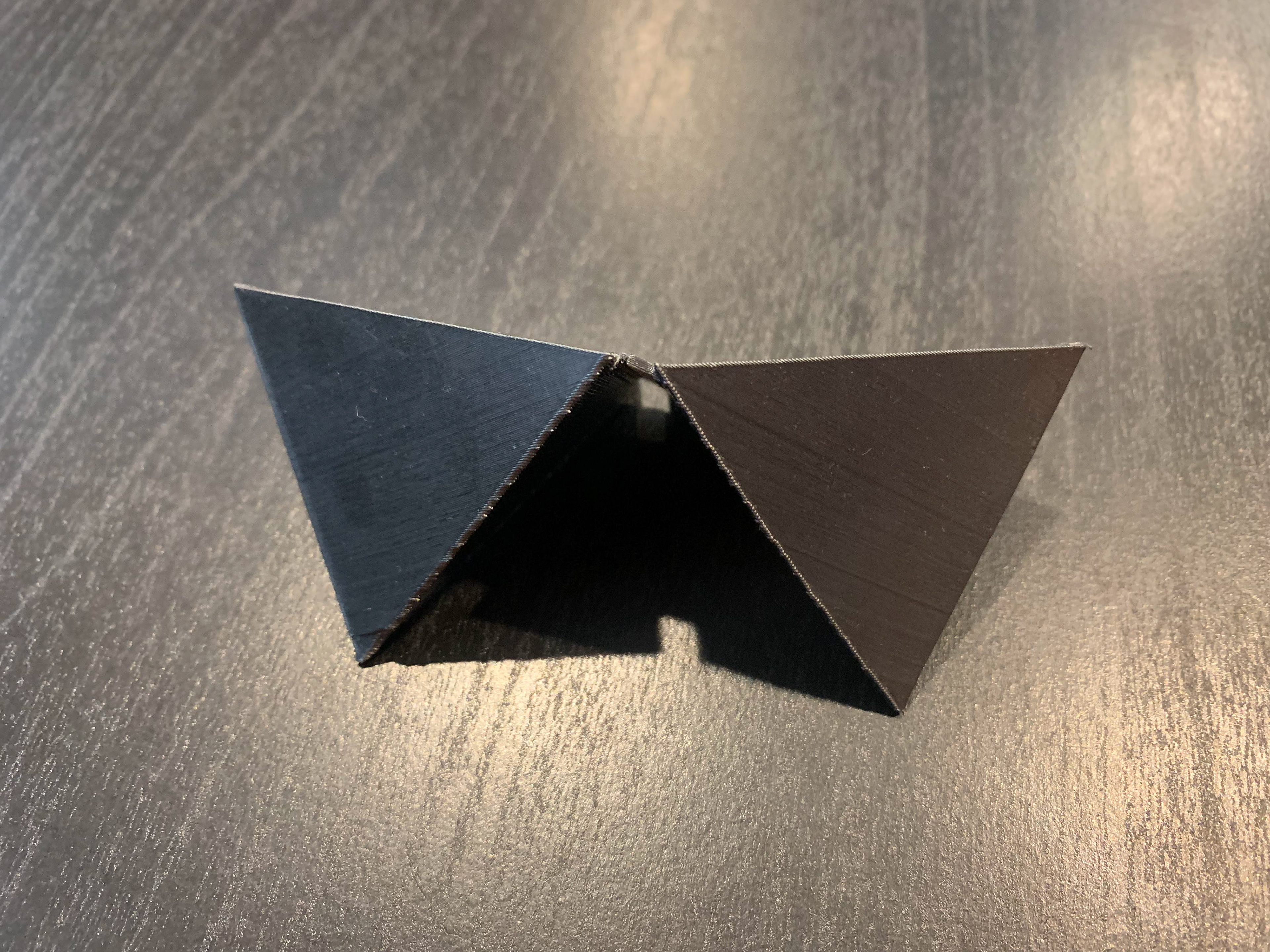

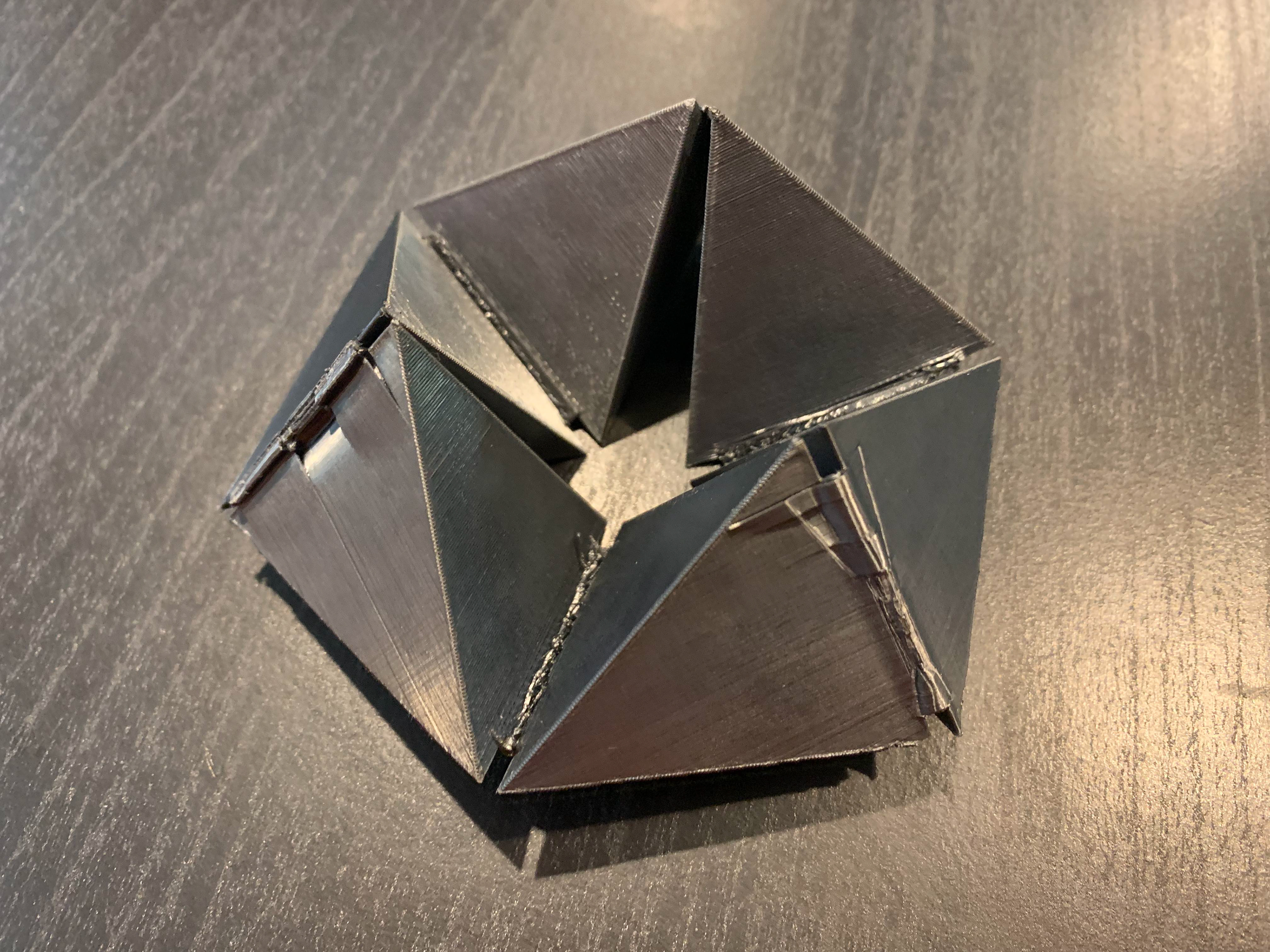

The first prototype was a shape testing, making the flexagon from 6 pyramidal-shaped pieces

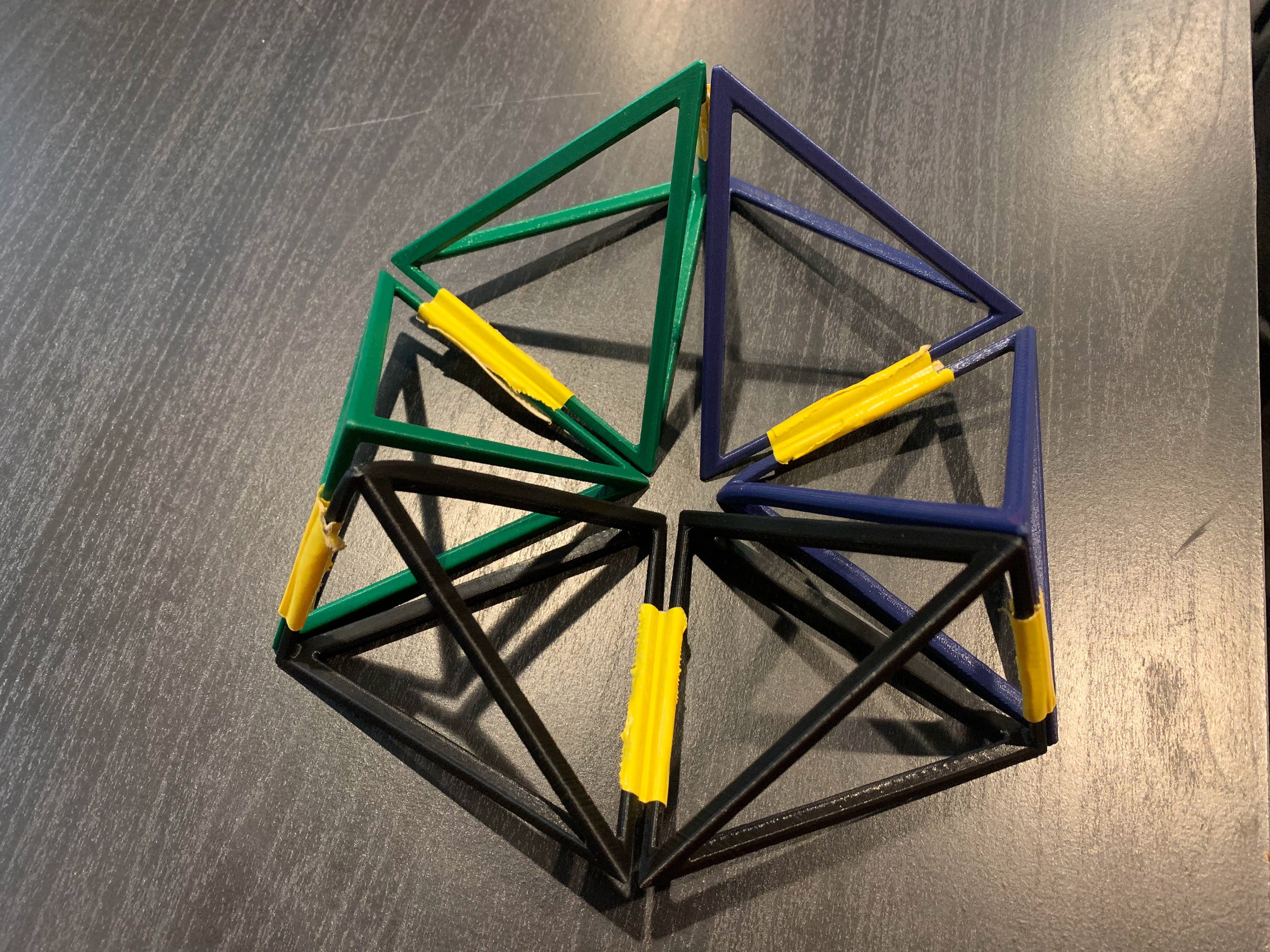

I went for a more artistic design for the next one, experimenting with only using the skeleton frame of the shape. In this stage I still had the pieces taped together to allow bending

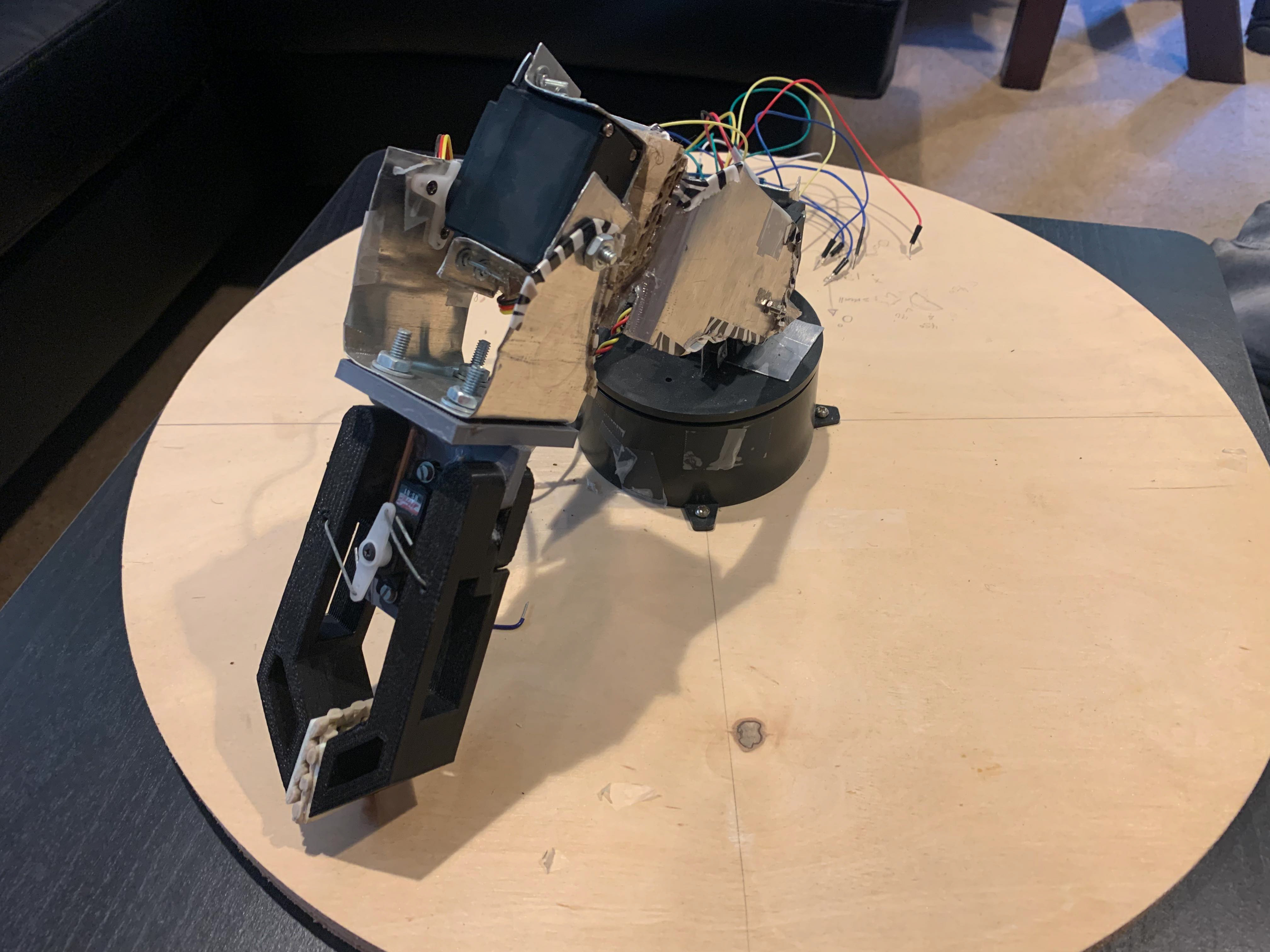

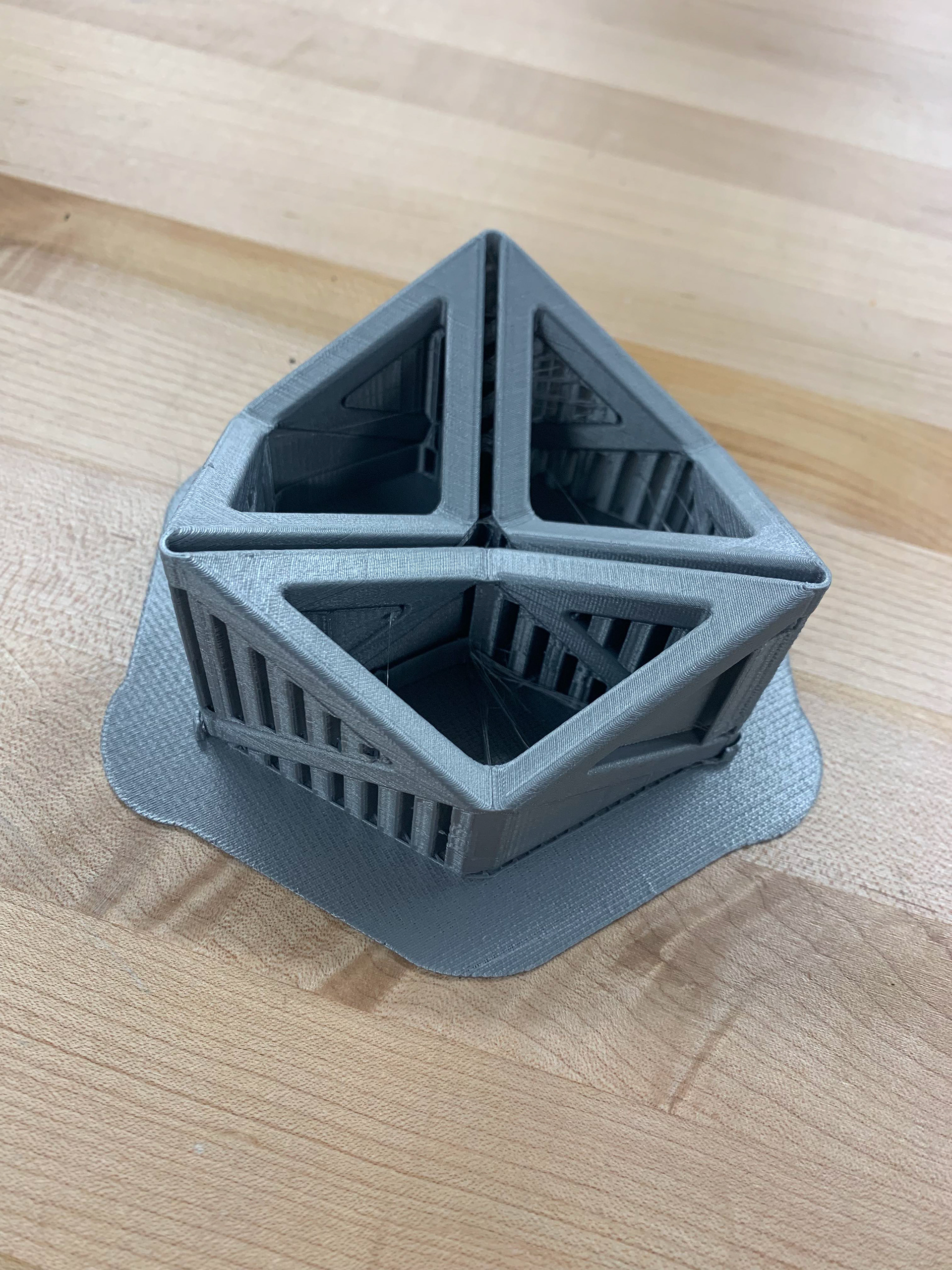

Next, I experimented with the actual hinges, creating the first single-piece 3D printed version.

For the final design, I went back to change the aesthetics into the similar skeleton frame structure from the earlier iteration